ChipXR

University of Florida

Immersive XR Training to

Transform Semiconductor Education

Responsibility

I end-to-end designed a mixed reality learning tool, collaborating cross-functionally throughout the process. Through multiple rounds of user testing, I played a key role in shaping the design direction and evaluating its educational impact.

Impact

Achieved +21% spatial knowledge gain than a video-based learning.

To be implemented in university courses and an internship training program ↗.

Published at CHI 2025 Late Breaking Work ↗.

Role

Lead UX Researcher

Lead UX Designer

Team

1 Product Manager

1 UX Designer

2 Software Engineers

2 Technical Artists

2 Content Experts

Timeline

Dec 2024 - May 2025

Tool

Figma

MAXQDA, Qualtrics

CHALLENGE

The current education lacks

resources for engineering students

to understand complex semiconductor chips.

Poor support for spatial understanding

3D chip structures are hard to understand

with traditional flat materials.

Lack of practical laboratory experiences

Hands-on labs are limited for students

due to cost and feasibility.

3D visualization

Hands-on lab practice

APPROACH

Leverage mixed reality (MR)

to overcome constraints.

Visualize complex chip structures.

Give hands-on experience virtually.

RESEARCH

Concept Testing

Since MR is an emerging technology, there was limited guidance to inform the design. So I tested an MVP to inform design direction and identify potential risks.

Goal

Identify potential usability risks

Method

Observation

Participants

12 engineering students

And I discovered..

Inefficient design creates

wrong cognitive load, which can

negatively impact learning.

Usability Issue

Virtual objects blended into the physical background,

causing users visual confusion that led to interaction errors.

🤯

🤯

🤯

🤯

🤯

💥

💥

💥

🤯

Cognitive overload!

We don't want to waste our brain power like this..

extraneous load

Unnecessary load from interaction failures :(

This looks right.

germane load

Productive load used for actual learning :)

Design Principle

How might we design

MR learning experience to

minimize cognitive overload?

ITERATE

Strategy 1

Add visual clarity

through organization and signifier

Signaling Principle

Cognitive Theory of Multimedia Learning

Before

Virtual objects are scattered throughout the scene.

After

Anchor the objects onto the grid.

Highlights

Signify interactable items.

Guiding Hands

Direct user attention for a clear guidance.

Strategy 2

Chunk into

digestible pieces

Segmenting Principle

Cognitive Theory of Multimedia Learning

Modular Lessons

STEP 1

Learn

Goal

Identify key components and their functions in chip structure

User Task

Interact with 3D chip component models with accompanying audio explanations

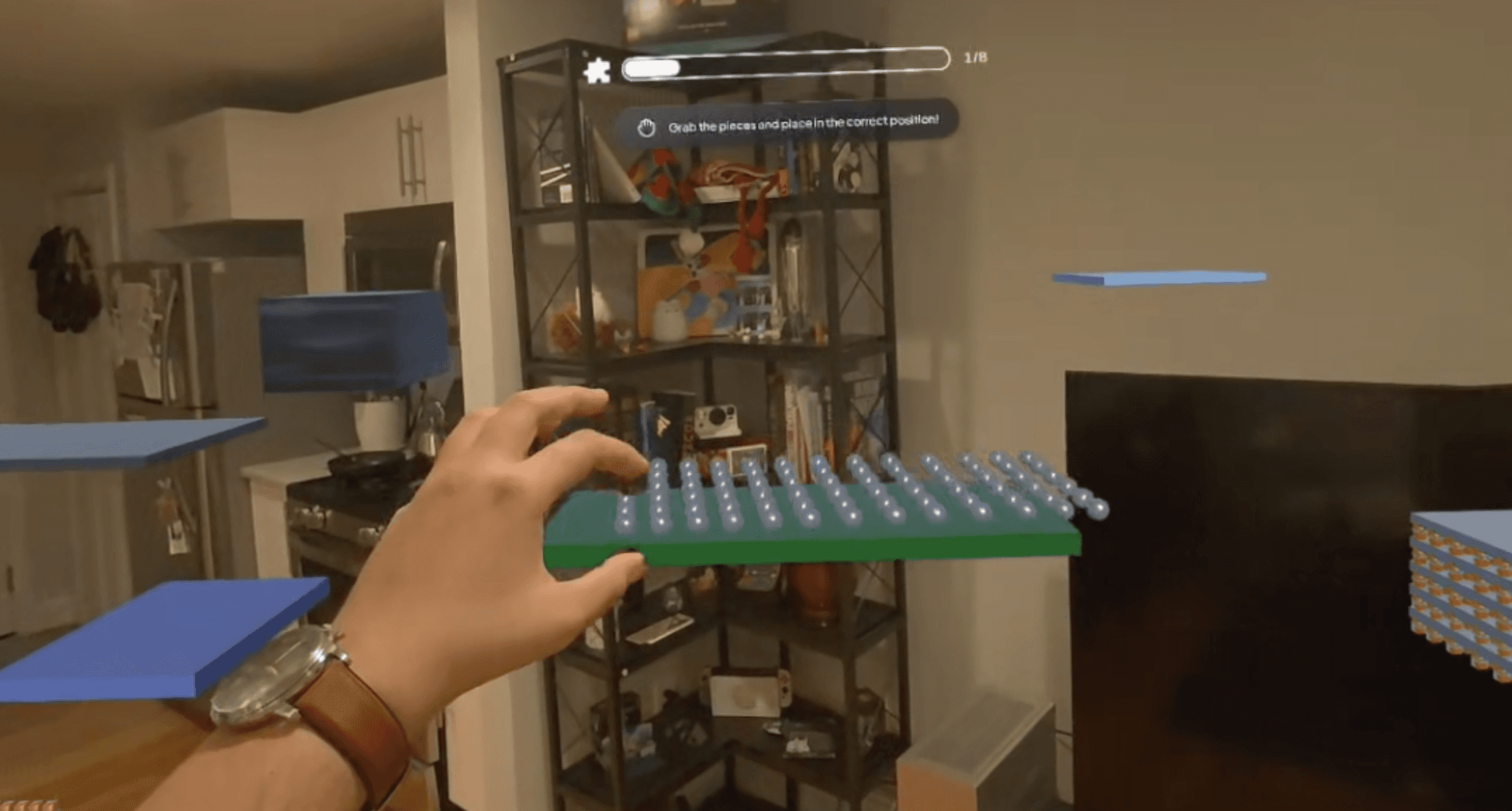

STEP 2

Assemble

Goal

Reinforce comprehension of the components and their relationships in the overall structure

User Task

Place component pieces in correct order to build complete structure

STEP 3

Fabricate

Goal

Understand the chip fabrication process by linking structural elements to procedural flows

User Task

Perform hands-on fabrication tasks to build the chip

Step-By-Step Fabrication

Fabrication Process

Photolithography

01

Etching

02

Electrodeposition

03

Wafer Bumping

04

Compute Die -

Base Die Attach

05

TSV Reveal

06

Electrodeposition

07

Solder Reflow

08

PCB Attach

09

TEST

User Testing

I used mixed-methods to evaluate the app comprehensively, and conducted two rounds of user testing.

Round 1

Quantitative Experiment

Goal

Evaluate learning effectiveness

Participants

24 engineering students studying relevant majors

Study Design

Within-subjects comparative study

ChipXR

vs

Video Lecture

Method

Survey

Tool

Qualtrics, R

Round 2

Qualitative Assessment

Goal

Get in-depth insights from target users

Participants

9 students target semiconductor course

Methods & Procedure

Think-aloud sessions

->

Focus groups

Tool

MAXQDA

IMPACT

ChipXR enhanced spatial understanding

and managed cognitive load efficiently.

LEARNING PROGRESS

Visual-Spatial Knowledge Gain

+21

% than video

COGNITIVE LOAD

Extraneous Load

-24.2

% than video

Germane Load

+13.2

% than video

Quotes from focus groups

“Videos usually have a couple side views,

but the 360 interactive view

made it easier to visualize”

“Especially in fabrication—mistakes are expensive.

That’s why VR is great.

You can fail without breaking anything”

“Getting that hands-on experience really helped

solidify what I had only understood

in a vague way before”

More projects?

*

*